Sealing element

(Factory)

Hydraulic and pneumatic sealing systems

,Rubber products

Scan it Mobile end

Chinese Station

Please select the groove size comparison table for the sealing product you need

O-ring

X-ring

Y/U-seal

J-dust

V-ring

Dumbbell seal

GSF glacier circle

GSJ stefan

Skeleton oil seal

Combined seal

常规 O-形圈 密封件 油封

液压、气动密封系统

更多 >>

O-ring

X-ring

Dumbbell seal

GSF glacier circle

GSJ stefan

R-shaft seal

Drum seal

J-dust seal

Y/U-seal

YXd shaft seal

YXD hole seal

V-pack sets

V-ring

skeleton oil seal

- 内容

- Installation design of O-ring seals

- Introduction to O-ring seals

- Introduction to the Properties of 17 Materials

- Sealing principle of O-ring seals

- Material Characteristics of O-ring Seals

- The Use Problems and Countermeasures of O-ring Seals

- Four major categories of O-ring seals

- Sealing principle and groove design standard of Y/U lip shaped sealing ring

- Other factors affecting the performance of O-ring seals

- The importance of wear-resistant rings (guide rings) in the use standards of oil cylinders

- Standard for using Y/U-shaped sealing ring and retaining ring

Sealing principle of O-ring seals

When the O-ring is installed in the groove, due to the depth of the groove being smaller than the O-ring, the O-ring is compressed (the thickness of the O-ring is less than the depth of the groove). This compression amount is called the compression allowance of the O-ring seal.

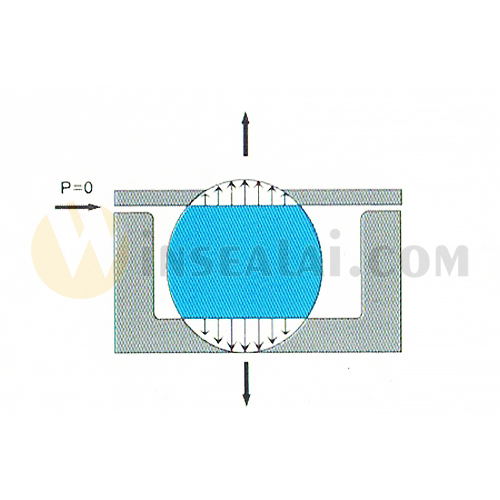

Under micro pressure, as shown in Figure 1, the O-ring exerts a sealing effect through its own rubber elasticity.

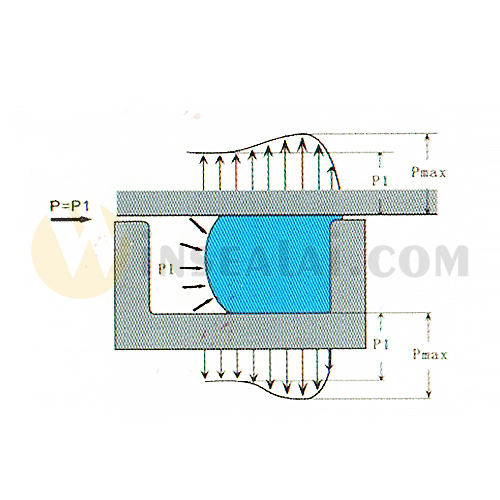

If hydraulic pressure is applied from one side, as shown in Figure 2, a high reaction force is generated by the load hydraulic pressure. This is called the self sealing effect of the O-ring seal.

|

Figure 1 |

Figure 2 |

Use of O-ring seals and retaining rings

When the O-ring is subjected to high pressure, it will produce extruded parts between the gaps. To prevent the extrusion of the O-ring seal, it is recommended to use a retaining ring.

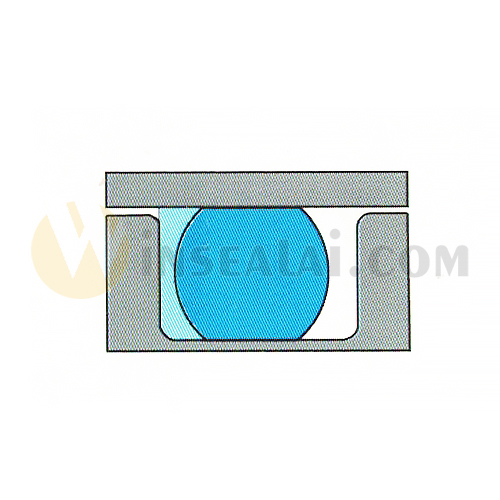

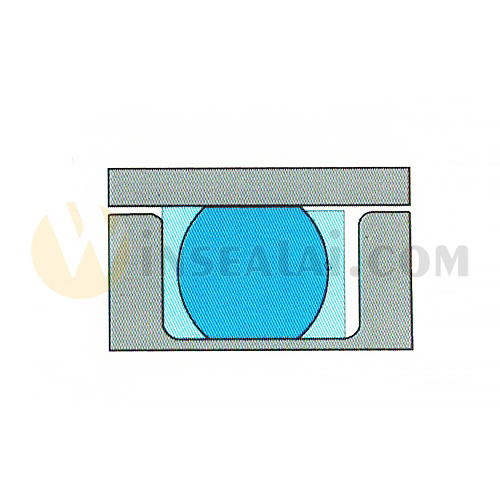

When the O-ring is subjected to two forces, the retaining ring is installed on both sides of the O-ring as shown in Figure 4. When only one force is applied, as shown in Figure 3, one retaining ring is installed on the opposite side of the pressure. However, if there is enough space, as shown in Figure 4, it is recommended to use two retaining rings even if only one side is under pressure.

In terms of the material of the retaining ring, polytetrafluoroethylene is mainly used. There are three types of O-ring retaining rings: circular, oblique cut, and spiral. From the perspective of use effect, the circular type has the best use effect; From the perspective of installation, inclined and spiral shapes are more convenient.

|

Figure 3 |

Figure 4 |

Performance parameter table

|

|

Static sealing |

Dynamic sealing |

|

Working pressure |

When there is no retaining ring, the maximum pressure can reach 20MPa; When there is a retaining ring, the maximum pressure can reach 40MPa; When using special retaining rings, it can reach up to 200MPa

|

When there is no retaining ring, the maximum pressure can reach 5MPa; When there is a retaining ring, the pressure is higher.

|

|

Movement speed |

The maximum reciprocating speed can reach 0.5m/s, and the maximum rotational speed can reach 2.0m/s | |

|

Temperature |

General occasions: -30 ℃~+110 ℃; Special rubber: -60 ℃~+250 ℃; Rotating occasions: -30 ℃~+80 ℃ |

|

|

Medium |

Refer to the "Material Characteristics Table" |

|

O-Ring Wire Diameter Tolerance

public errand

During the vulcanization process, the size of the elastomer will change. The performance of the material, the shape of the mold, and the vulcanization process determine the size of the shrinkage.

The following table provides the tolerances for wire diameter d2. Please refer to the ISO3601 standard for dimensions not listed in the table.

Line diameter tolerance table

|

O-ring diameter d2mm |

public errand ±mm |

|

0~1.8 |

0.08 |

|

1.80~2.65 |

0.09 |

|

2.65~3.55 |

0.10 |

|

3.55~5.30 |

0.13 |

|

5.30~7.00 |

0.15 |

|

7.00~8.00 |

0.18 |

|

8.00~10.00 |

0.21 |

|

10.00~12.00 |

0.25 |

- 内容

- The importance of wear-resistant rings (guide rings) in the use standards of oil cylinders

- Standard for using Y/U-shaped sealing ring and retaining ring

- Sealing principle and groove design standard of Y/U lip shaped sealing ring

- Other factors affecting the performance of O-ring seals

- Installation design of O-ring seals

- Four major categories of O-ring seals

- The Use Problems and Countermeasures of O-ring Seals

- Sealing principle of O-ring seals

- Material Characteristics of O-ring Seals

- Introduction to the Properties of 17 Materials

- Introduction to O-ring seals

Focusing on high-end sealing

Foreign Materi

Customized development plan

Maximum value

Professional packaging services

Packaging supply

Regular size query

Improve efficiency

Professional online services

Quick response

Contents

Sealing Classification

Sealing repair kit service

Seal machining center

WINSEALAI.COM

Precision molds

Technical support

R&D customization

Information Center

Industry News

FAQ

Good and bad seal

About Us

Company Introduction

Quality control

Contact us

Copyright © 2022 Winsealai.com, All Rights Reserved

粤ICP备2021081444号-1

粤公网安备 44060502002654号